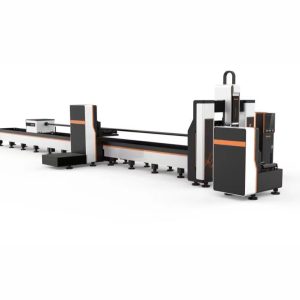

Considering a high-end laser cutting solution tailored for both precision and durability? Our “Exchange Platform Large Surround Laser Cutting Machine” could be your ideal pick, infusing state-of-the-art technology with impeccable performance. Let’s delve into its defining features:

Exchange platform large surround laser cutting machine Features:

- Welded Bed: Ensures a robust foundation for precision cutting, providing stability under all conditions.

- Compression and Shock Absorption: This feature minimizes machine vibrations, ensuring a smoother cutting process and optimal accuracy.

- Fourth Generation Aviation Aluminum Beam: Offers the perfect blend of lightness, durability, and structural rigidity, optimizing performance.

- Imported Parts for Precise Control: Guaranteeing consistent high-performance and longevity, testament to our commitment to quality.

- Infrared Night Vision Day and Night Monitoring: Provides continuous safety monitoring, assuring operations 24/7 without compromise.

- Autofocus Laser Head: Facilitates quick and precise focusing, eliminating the need for manual adjustments.

- Higher Switching Efficiency of Dual Platforms: Speedy platform interchange ensures uninterrupted production, significantly enhancing operational efficiency.

- Efficiency: The exchange platform feature reduces machine downtime by quickly swapping out cut materials with new sheets, improving overall operational efficiency.

- Safety: The “surround” in its name may indicate enhanced safety features, possibly a complete enclosure or protective surround to contain any laser scatter, protecting operators and other workers.

- Precision: Despite its size, these machines are expected to offer high precision and accuracy in cutting.

- Versatility: Capable of cutting a range of materials, from metals to plastics and even ceramics, depending on its laser source.

- User-friendly Interface: Modern machines often come with intuitive control software, making operations smoother and more efficient.

Exchange platform large surround laser cutting machine Applications:

- Heavy Industry: Given its large size, it can be used in industries that handle large metal sheets or plates like shipbuilding, railway, and construction equipment manufacturing.

- Aerospace & Defense: Cutting and shaping large aircraft parts, armored vehicles, or components that need precise laser cuts.

- Energy: Specifically in renewable energy sectors, where large metal parts for wind turbines or solar panel mounts are required.

- Automotive: For shaping and designing large vehicle parts or components.

- Metal Art & Sculpture: Crafting large metal installations or artworks.

- Industrial Equipment Manufacturing: Producing large machinery parts or components.

This machine is not just about specifications; it’s a harmonious blend of technology and user-centric design, aiming to deliver unmatched value.

Product main parameters

| Maximum operating speed | 100 m/min |

| X/Y positioning accuracy | 0.03MM |

| X/Y repeated positioning accuracy | 0.02MM |

| Working voltage | 380V /50HZ |

| Total machine power | 15KW-100KW |

| Supported laser power | 1000W-30000W |

| Machine operating temperature | 5-45°C |

| Operating humidity of machine tool | ≤80% without condensation |

| Transmission mode | rack double drive |

| Product series | 3015/4015/6015/4020/6020/6025 |

| Processing format | 3000×1500MM 4000×1500MM 3000×2000MM 4000×2000MM 6000×1500MM 6000×2000MM 6000×2500MM |

| Cutting thickness range | 0.2MM-50MM |

| Product width | 1.5M/2M/2.5M |

| Cut length | 3M/4M/6M/12M |

| Support laser power | 1000W/2000W/3000W/6000W/12000W/20000W/30000W |

Exchange platform large surround laser cutting machine Cutting product display

If the “Exchange Platform Large Surround Laser Cutting Machine” aligns with your requirements, don’t hesitate. For detailed insights, a bespoke consultation, or a competitive quote, our dedicated team is always at your service. Seize the opportunity to elevate your operations. Reach out today!