1. Introduction

Water jet cutting machines represent a pinnacle of innovative technology in the manufacturing sector, harnessing the power of high-pressure water streams combined with abrasives to precisely cut through a myriad of materials. With JIUYING, you’re introduced to this cutting-edge technology designed to revolutionize your cutting and design needs.

2. Basic Principles of Water Jet Cutting

Water jet cutting is a subtractive manufacturing process that carves out desired shapes and patterns by ejecting a concentrated, high-speed jet of water onto a material’s surface.

- Water Pressure: At the heart of this technology is the conversion of water into a high-pressure stream, sometimes reaching pressures up to 100,000 psi. This high-pressure water is pushed through a small-diameter nozzle to concentrate the force.

- Abrasive Cutting: For tougher materials like metals, ceramics, or thick plastics, an abrasive material, often garnet or aluminum oxide, is introduced into the water stream. This combination enhances the cutting capability, turning the water jet into an abrasive water jet cutter. The abrasive particles erode the material in its path, producing a cut.

- No Heat Generation: Unlike many traditional cutting methods, water jet cutting is a cold process. This means there’s no thermal stress applied to the material, ensuring the structural integrity of the cut material remains unchanged.

- Control and Precision: The trajectory of the jet is controlled using computer numerical control (CNC) and CAD (Computer-Aided Design) software, allowing for intricate designs and patterns to be cut with high precision.

- Layered Cutting: Due to the sheer force and precision of the jet, it’s possible to cut stacked layers of certain materials simultaneously, optimizing production times.

- Waste and Kerf: The width of the cut (kerf) is minimal, which means less waste material. This narrow kerf, combined with precise computer controls, allows for efficient nesting of parts to maximize material usage.

3. Advantages of Water Jet Cutting

- Versatility: From metals to rubber, JIUYING machines excel.

- Precision: Known for unmatched accuracy.

- Cold Process: Eliminating heat-affected zones.

- Eco-friendly: Championing minimal waste and zero emissions.

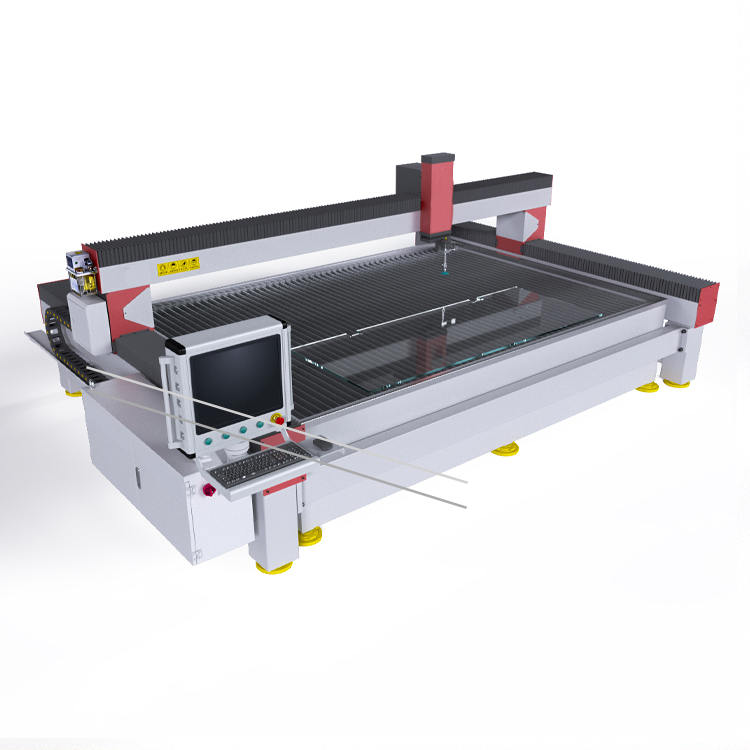

4. Components of a JIUYING Water Jet Cutting Machine

Essential components like the high-pressure pump, abrasive hopper, precision cutting head, intelligent control software, and catcher tank are crafted with perfection at JIUYING.

5. Operating the Machine: A JIUYING User’s Guide

Safety is paramount. With your material in place, utilize our intuitive CAD designs. Tweak parameters, then watch as JIUYING’s precision comes to life. Maintenance is key for optimal performance.

6. Key Parameters and Their Cutting Influence

Control pressure for speed and quality. Adjust the nozzle for precision. Choose abrasives for power, set the feed rate, and remember: water quality is pivotal.

7. Advanced Techniques by JIUYING

Experience tilt-angle cutting, embrace multi-head productivity, and for those seeking creativity, our 3D cutting offers a new dimension.

8. JIUYING Machines: Limitations are Minimal

Despite their vast capabilities, material thickness can pose a challenge. Tapering effects are minimal, but regular maintenance ensures machine longevity.

9. JIUYING’s Footprint Across Industries

From aerospace to art installations, JIUYING’s Water Jet Cutting Machines have made their mark, delivering precision and beauty in every cut.

10. Conclusion JIUYING isn’t just about technological advancement; it’s about pioneering a brighter, sharper future in cutting solutions.

Interested in integrating the power and precision of JIUYING into your operations? Send us an inquiry and let’s discuss how our water jet cutting machines can revolutionize your projects.